Understanding the Basics: Tube Bending

The demands placed on today’s fluid systems are much tougher than they were a decade ago. Leaks that were once considered nuisances are now classified as fugitive emissions and hazardous spills, problems that can shut down plants. Modern processes are pushing pressure, flow, and temperature requirements to new heights every day, yet the basic concepts of system design have not changed over the years. The incorporation of tube bends in fluid system design is important from many different perspectives – procurement, installation and performance.

Tube bending has many benefits in terms of cost effectiveness, production and system performance. By economizing expenses related to additional fittings and connection points, not only material costs but also procurement, storage and labour costs can be significantly reduced. Tube bends also produce better flow characteristics based on the smooth internal surfaces reducing flow losses and drag, as well as contributing to reduced pressure drop and turbulence, all while increasing system performance.

Industry Best

In terms of value and performance, Swagelok Tube Benders lead the industry. They’re robust and reduce installation time and effort, as well as the potential for wrinkling or other damage to the tubing during bending. Depending on your application, Swagelok has the tools you need. Our hand tube benders are appropriate for smaller, instrument tubing applications (up to ½ inch OD), while our bench top bender and electric tube bender handle tubing sizes up to four inch OD. Have a small project or difficulty justifying a capital expenditure for equipment purchase? We also offer equipment rentals, including tube bending equipment, to meet your needs.

Make the Learning Curve Easier

The tech tip video below covers the basics of tubing selection, as well as operation of our hand tube bender and procedure for completing two single bends with a measured degree of separation.

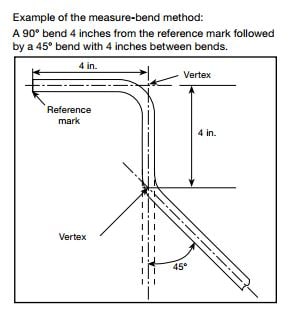

The "Measure-Bend Method"The measure-bend method is the preferred tube bending procedure, and is taught in our Tube Bending Essentials training course. It generally requires less math, is faster, and is more adaptable to multiple runs of tubing:

|

Work Smarter, Not Harder

More connections means greater potential for leaks. The Swagelok Tube Bending Essentials course offers foundational knowledge needed to introduce bent tubing to your system to eliminate connections and leak points found in traditional threaded or welded pipe systems. Students will work through multiple practical examples to measure, cut, bend, and install tubing into a pre-fabricated instrument panel. The course is designed to simulate real-world applications and troubleshoot actual scenarios encountered in the field. Benefits include: reduced installation time, less wastage, improved flow, eliminated leak points and increased safety.

Learn more about the Swagelok Essentials Training classes, as well as our schedule of upcoming training dates.