Learn From the Best | Learn From Swagelok

Learn From the Best | Learn From Swagelok

Quality Tube Fitting + Correct Installation = Leak Free Assembly

Investment in quality tube fittings and fluid system components is only one part of the Leak Free Assembly equation. Correct installation practice is equally important, in both high and low energy systems, to combat system leakage and the prevalence of fugitive emissions – so much so that the Swagelok Tube Fitter’s Manual devotes an entire chapter to Tube Fitting Handling and Installation.

Stop Leaks at the Source

Correct installation of instrument tube fittings does not involve any specialized tooling or difficult, technical procedures; yet time and again, our Energy Emission Specialists document incorrect installation as one of the most common root causes of leakage while on-site conducting energy audits.

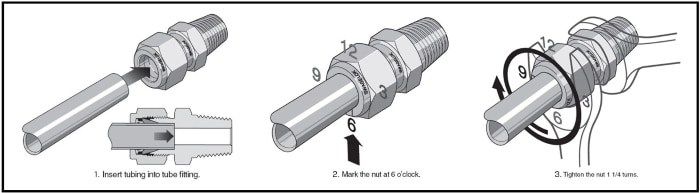

Consider the following three-step procedure for manual installation of Swagelok Tube Fittings up to 1 inch or 25 millimetre:

- Fully insert the tube into the fitting and against the shoulder; rotate the nut finger-tight.

- Mark the nut at the 6 o’clock position.

This will be your reference starting position. - While holding the fitting body steady, tighten the nut 1 1/4 turns to the 9 o’clock position.

For 1/16, 1/8, and 3/16 inch or 2, 3, and 4 millimetre tube fittings, tighten the nut a 3/4 turn to the 3 o’clock position.

Correct installation of instrument tube fittings not only mitigates the potential risk of leakage, it also contributes to lowering costs through a decrease of waste and rework, and increases workplace safety.

Quality Technical Instruction

Leak tight fluid systems don’t happen by accident – it takes quality components and installation know-how. At Swagelok, we provide quality components and encourage our customers to train their installers on proper installation, including tubing selection and preparation, as well as the Swagelok tube fitting installation instructions described above. We not only encourage training, but we also offer hands-on, practical training courses for our customers – Swagelok Essentials Training.

With Swagelok Essentials Training our customers learn the fundamental, theoretical principles behind selecting, handling and installing fluid system components. These principles are then reinforced with hands-on examples. Both theoretical knowledge and practical skills are then tested in a final examination upon which a certificate of completion is awarded to the customer. With more and more companies standardizing their fluid system training with Swagelok, the knowledge, skills and certificate are valuable assets.

Convenient and Flexible

At Swagelok, we’re committed to providing our customers with custom training services that align with their specific needs and concerns. All training sessions are led by our experienced and certified Swagelok trainers. We provide scheduled training sessions at each of our locations or, if you require training on-site or have a large group, we'll bring Swagelok Essentials Training to you.

To access more information on Swagelok Essentials training, review course descriptions and course schedules, or register online, click on the banner below.