The Virtue of Thread Identification

The Virtue of Thread Identification

Even the most experienced industry professionals sometimes have difficulty identifying threads, regardless of their thread identification procedure and the quality of their gauges. That's why we’re outlining our simplest form of thread identification as well as the tools required to correctly identify any thread you may come across.

Where Do We Start?

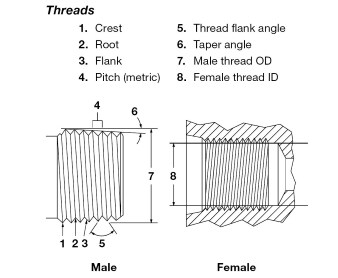

Swagelok fittings, valves and other components all have one thing in common: threads. To ensure that you’re connecting compatible connections, we need to discuss some general terms and characteristics which apply to all threaded connections:As you can see from the cross-sectioned image above, there’s more to threads than meets the eye. All threads, regardless of being straight or tapered, will have crests and roots with the section between the crest and root being the flank. When dealing with straight threads, the crests are the same diameter whereas with tapered threads, the crest diameter goes from larger to smaller as measured along the thread. In most cases, it can be quite easy to make this determination with the naked eye, but we always recommend using a caliper to measure the thread OD at the first, fourth and last full thread to ensure correct thread identification.

NPT, Yeah You Know Me

The next factor we need to consider for thread identification is the pitch of the threads. The pitch of the thread is the distance from crest to crest, and is usually expressed as the number of threads per inch.

Straight threads come in three standards kinds of measurements – SAE (Society of Automotive Engineers), ISO 228/1 (also known as BSPP or British Standard Parallel Pipe), and metric. Tapered threads also have several standard kinds of measurements, the most common being NPT (National Pipe Thread), ISO 7/1 (also known as BSP or British Standard Pipe), and metric.

Generally speaking, a pitch gauge is used to correctly identify the thread pitch. With three different flank angles – Whitworth, Unified and Metric – and very similar thread specifications across all standards, it is important to make sure adequate time is spent to ensure the correct fit.

Learn to identify thread pitch and size using calipers, a pitch gauge, and Swagelok's Thread Identification Giude.

Armed with these basic principles, the requisite tools (caliper and pitch gauge) and the Swagelok Thread and End Connection Identification Guide, you will be on your way to proficiency in thread identification. If you'd rather get more hands on, we offer several training courses that offer further insight into thread identification. Of course, we’re also here to help assist and guide you through this process; contact us today.