Evaluation & Advisory

How Much Did Your Facility Spend in Electricity Last Year?

Learn how we managed to find nearly $500k of cost avoidance for our customer

Generally speaking, the word audit is a term that strikes fear among tax-paying citizens of the world, especially in springtime around tax filing season. However, not all audits are bad, especially when they’re focused on decreasing costs.

We know first-hand the benefits of auditing compressed air systems. An audit provides an opportunity for a comprehensive assessment of the health of an entire system, or a single element of a system, with the goal of increasing efficiencies and productivity, while decreasing energy costs.

Air Ain’t Cheap

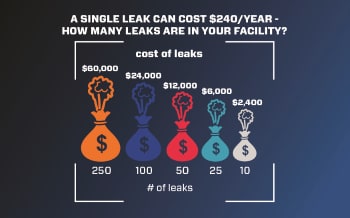

Compressed air is one of the most expensive uses of energy in a production facility. Approximately eight kW of electricity is required to generate one kW of compressed air. Over 70 percent of all manufacturers have compressed air systems in operation – these systems are vital, powering a variety of equipment including control systems, machine tools, material handling and production equipment, enabling the overall operation and efficiency of the plant.

We’ve found that about two-thirds of energy costs for compressed air can be significantly reduced without major capital cost, and a typical manufacturing or production facility can save greatly by having a comprehensive assessment of their utility air system.

Why Swagelok?

Comprehensive - We have the capability to review a complete system, or any individual element of a system

Thorough - We provide detailed, comprehensive reports with prioritized recommendations and scheduled verification of the prescribed improvements

Unparalleled Client Experience

With Swagelok Evaluation & Advisory Services, we help clients attain their operational goals in the areas of efficiency, reliability and cost reduction. Here’s what to expect from us:

Dedication to your success - We are committed to providing high-impact evaluation services and training.

Hands-on Support - Regardless if we’re providing best-in-class training or leveraging our expansive experience during an evaluation, we work shoulder-to-shoulder with your team in your plant.

Flexibility - Our evaluation and advisory services are tailored to meet your exact needs.

Values - Every day, our business lives and breathes the Swagelok values of quality, innovation, continuous improvement, integrity, respect and customer focus.

Results You Can Count On

You expect performance, efficiency, reliability and safety from your in-plant utility systems. You deserve an advisory and training expert who shares those priorities and is committed to your success with quantifiable results.

In 2017, our Evaluation & Advisory Services saved our customers tens of thousands of dollars. Learn more about the true value of compressed air and how you can save.