Best Practice Proper Tubing Placement

Best Practice: Proper Tubing Placement

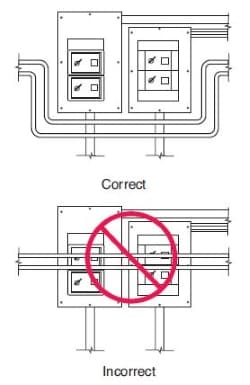

There is a lot to consider when running tubing lines throughout a facility. Never block controls, panels, or screens with tubing lines – always route around instrumentation to avoid prohibiting operator/maintenance access.

When running multiple lines together, tubing should be stacked vertically to prevent dirt, corrosives, and other contaminants from collecting in the space between the lines. Avoid stacking lines horizontally, but if tubing must be ganged horizontally, it should be covered to prevent potential problems.

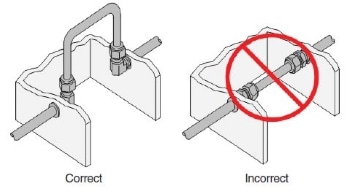

Design for Fitting Accessibility

To ensure proper bottoming of tubing and correct installation, installers should avoid springing tubing into position. Utilizing additional elbow fittings allows for expansion, prevents side-load stress, and makes it easier to maintain the system.

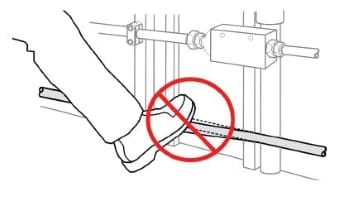

Avoid “Rail” Locations

Properly Support Tubing

Many fluid systems are subject to repeated impulse and vibration. Proper tubing support minimizes these harmful effects to prevent sagging and improve the reliability of tubing, fittings, and other components throughout a facility.

The specific type and location of tube supports depend on the design of the system. Regardless of the application, supports are especially important around elbows, tees, bends, and heavy in-line components such as valves. Always consult published guidelines for support selection/spacing to determine best practices for different industries.

For more information, or additional reference, download a copy of the Swagelok Tube Fitter’s Manual and consult chapter 3, Tubing and Tube Fitting Handling and Installation.

Swagelok Tube Fitters ManualSwagelok Essentials Training