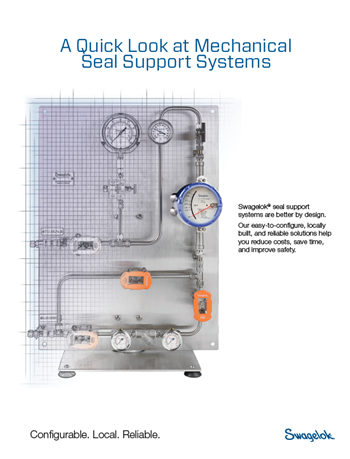

Seal Support Systems

Configurable. Local. Reliable.

Mechanical Seal Support Systems

API 682 solutions configured locally from the company you trust

Swagelok's mechanical seal support systems are designed to maximize the life of mechanical seals and the reliability of rotating equipment by maintaining lubrication and system pressure and providing properly conditioned fluid flows.

Read customer testimonials on our API-682 Seal Plans

Less Leakage Saves Money, Reduces Labor, and Improves Safety

Nearly 40%1 of all unscheduled critical pump shutdowns are caused by mechanical seal failures. While all seals leak, mechanical seals and mechanical seal support systems help control leakage, saving money, reducing labor, and improving safety. To protect your operations, it's best to use a seal support system that is customized to your application's specific needs and designed to reduce costly leak points.

1http://machining.grundfos.com/media/16611/shaftseal_chapter5.pdf

Simplified Installation and Maintenance Reduce Labor

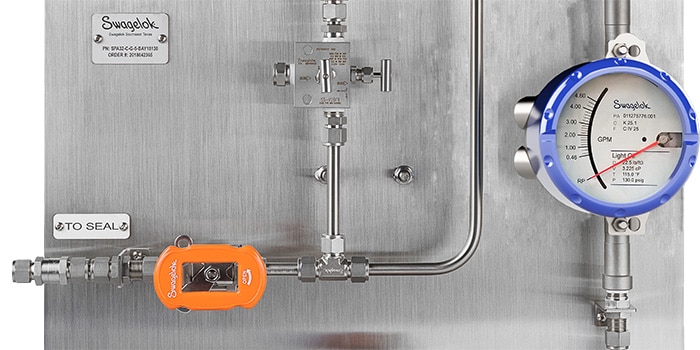

Swagelok's mechanical seal support systems are guided by API 682 and designed to avoid pipe threads to limit the number of leak points wherever possible. Standardization is key in improving efficiency, and our customizable, repeatable design and assembly result in fast, efficient replacement, maximizing uptime. Where beneficial for system troubleshooting, maintenance, or safety, additional options are available to ensure the plan you choose fits your requirements.

Local Support Maximizes Uptime

Swagelok Calgary is your local source for API 682 mechanical seal support plans configured for your application. To help with labor, installation, and inventory costs, seal plan kits that bundle plan components are also available.

You can depend on us to provide the components or services you need, backed by the Swagelok Limited Lifetime Warranty. Our local customer support keeps your plant running whether it's design services, custom assembly, or sourcing components. Our Custom Solutions team can help with assembly if you are short-staffed or troubleshoot design or application concerns.

Our certified technicians undergo a comprehensive training and recertification program every three years to ensure your system is assembled to strict guidelines, providing you with reliable, consistent mechanical seal support systems.

We offer assistance with the following:

- Fabricating and assembling customized API 682 systems with components especially suited for your application

- Creating CAD drawings and piping and instrumentation diagrams (P&ID) designed to your specifications

- Assisting with component selection and generating bills of materials

- Welding, tube bending, and other value-add services