Safety First: Labeling Critical Components

Safety First: Industrial Fluid System Checklist

Safety First Topic:

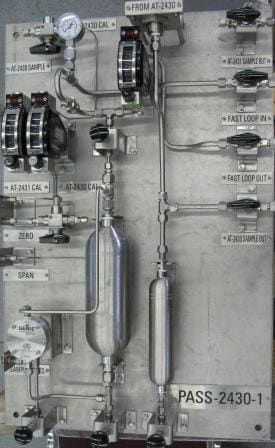

Labeling Critical Components

In most cases, the more information we're given, the better our judgement becomes. Labeling components is a simple way to keep vital information easily accessible. Installing specific tags on machinery and hoses that show what is going on within the system, enable the operators to make the appropriate changes. In addition, you can color code handles, tubes, and pipes throughout your system. The information on a tag or label can vary between applications, and best practices at your company.

Typical information that you might find on a tag, where applicable, would be:

- Component Part Number

- Operational Temperatures/Pressures

- Operational Hazards (such as extreme high/low temperatures)

- System Media

- Direction of System Flow

- Canadian Registration Number (CRN)

- Original Purchase Order Number

- Specific Date of Manufacture/Installation

Methods of tagging components can also vary when you consider the complexity of the system. In some cases, only one or two components would benefit from being tagged by simply attaching the tag to a valve handle, tubing or a component body out of the way of any moving components, would suffice. Whereas a complex system with various pressures, temperatures, flow paths and system medias would benefit greatly from being properly tagged and labeled.