Pressure Regulators: The Basics

Pressure Regulators: The Basics

Selecting a regulator can be a complex process that first requires a general understanding of how a pressure regulator works. A regulator’s main purpose is to maintain a constant pressure on one side of the regulator even through there is a different pressure or fluctuating pressure on the other side. The primary reason for regulating pressure is to maintain a consistent, repeatable and accurate delivery pressure to processes and process equipment – either upstream or downstream – so as to reduce the likelihood of process variability and to protect sensitive equipment and instruments.

Two Types of Pressure Regulator

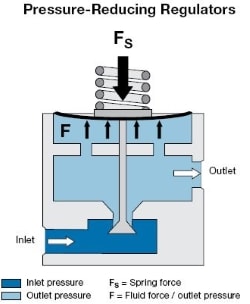

The function of a pressure-reducing regulator is to reduce pressure downstream and to keep this pressure as constant as possible

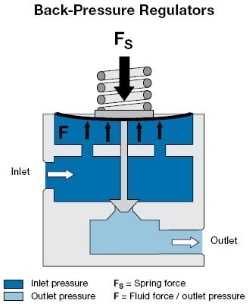

The function of a back-pressure regulator is to keep upstream pressure, or inlet pressure, below a set pressure. This means the regulator can either open in case of excess pressure or close when the pressure drops below the desired set pressure. This is accomplished by the fluid force (F) being equal to or slightly lower than the load force (Fs) causing the poppet to close.

Three Common Design Components

Every Swagelok pressure regulator has three common design components:

- Loading mechanism (spring, dome, or combination)

- Sensing mechanism (diaphragm or piston)

- Controlling mechanism (poppet)

Loading Mechanism

The loading mechanism is the component of the regulator that balances the force or pressure. In a spring-loaded regulator, a coil spring is used to generate a load (Fs) against the sensing mechanism, and can be adjusted by turning the handle or adjustment screw of the regulator. In a dome-loaded regulator, a gas is fed into the dome chamber above the sensing mechanism at a pressure equal to or slightly above the desired outlet pressure; this volume of gas is used like a spring. The spring- and dome-loaded mechanisms can be used in combination – essentially providing the function of a differential pressure regulator – with the reference pressure provided by the dome and a bias pressure provided by the spring.

Sensing Mechanism

The sensing mechanism is the component separating the spring/dome force and the fluid force, and senses changes in pressure allowing the regulator to react and restore the original set pressure. A diaphragm sensing regulator has a large, flat piece of material usually made of an elastomer, PTFE or metal depending on the application. A diaphragm is usually used for low-control, pressure sensitive applications. A piston sensing regulator utilizes a cylindrical metal component (piston), and is typically used to regulate higher pressures than a diaphragm can withstand. They are also more resistant to damage caused by pressure irregularities and have a short stroke to maximize cycle life.

Controlling Mechanism

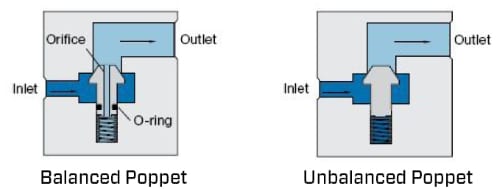

The controlling mechanism, also known as a poppet, acts to reduce a high inlet pressure to a lower outlet pressure. There are two designs used in Swagelok regulators. In a balanced poppet design, the area on which the inlet pressure acts is reduced due to the orifice through the poppet and balancing o-ring. The advantages of this design are a reduced sea load, less sensitivity to Supply Pressure Effect (SPE), and the ability to have a larger seat for more flow.

In an unbalanced poppet design, the inlet pressure provides the majority of the shutoff force. Unbalanced poppets are generally used in small regulators or larger regulators in low-pressure applications.

The Bottom Line

At Swagelok, we’re happy to help customers understand their application needs, and aid in the selection of the appropriate regulator for the job. Complete our Service Request Form, or, better yet, give us call to discuss your needs.

For more information on the K Series and RHPS Series pressure regulators, please review the Swagelok Pressure Regulator product literature.