Small Bore Solutions Equal Big Cost Savings

Small Bore Solutions Equal Big Cost Savings

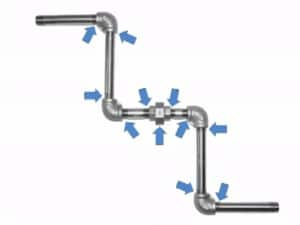

Small bore tubing systems offer simplicity, cost-savings and superior performance over traditional piping systems. Today, most take advantage of tubing systems for fluid transfer functions in applications 1/2-inch (12 mm) diameter and under, but in applications ranging from 3/4-inch to 2 inches (19 to 50 mm), pipe continues to be the traditional choice. Tradition, however, comes with added costs - in many cases, it's a savings opportunity that is unknown and often goes unexplored.

Swagelok tubing systems versus traditional piping systems.

Reduce Installation and Maintenance Costs

Consider the requirements for a typical piping project: If it is threaded pipe, there are the pipe stands, dies, cutting oils, sealants, and tapes. Then there is assembly, testing, disassembly, rework, and reassembly.

For any job that requires welding, there is the additional need to obtain a qualified welder, welding equipment, and consumables. Then depending on the job, there can be the need for weld permits, air tests, firebox, tacking, weld quenching, finish welding, purging, passivation, and inspections.

Any way you look at it, the process can be complicated and time consuming. When comparing tubing and piping systems, the advantages of tubing are many:

- Ease of installation – anyone can install Swagelok tube fittings with simple tools. Gone are the threading tools and sealants.

- Lower pressure drop – tubing systems offer gradual bends and a smooth internal diameter which equates to reduced turbulence and increased system performance.

- Fewer connections needed – bending tubing does not require a break in the line nor an elbow connection, significantly reducing the number of potential leak points.

- Better strength to weight ratio – the full wall thickness in tubing systems is used to contain pressure. Piping systems require a greater wall thickness to accommodate threaded connections.

- Leak tight – Swagelok tube fittings are leak tight without requiring any additional sealing compounds or tape.

- Easy maintenance – there is no need for sequential disassembly with Swagelok tube fittings; every fitting acts as a union.

Simpler, Safer, Faster

In a matter of minutes, anyone in your plant can learn to assemble, and install Swagelok tube fittings correctly the first time. Swagelok small bore solutions eliminate the oils, sealants, dies and threading equipment with leak-tight, reliable Swagelok tube fittings. This means potential rework and maintenance are significantly reduced.

Swagelok tube fittings offer vibration-tolerant, pressure containing connections. And as small bore tubing systems use no heat or weld gases, they are ideally suited for installation in hazardous or confined spaces.

Using Swagelok small bore solutions also dramatically improves productivity. Tubing systems are fast to install. Bending tubing reduces the number of connections in a system and remakeable Swagelok tube fittings reduce the time required to maintain or modify systems. This means you can install more systems in less time and re-allocate saved resources to other areas of your plant.