CNC Tube Bending

CNC Tube Bending Flanks Increased Fabrication and Assembly Capability

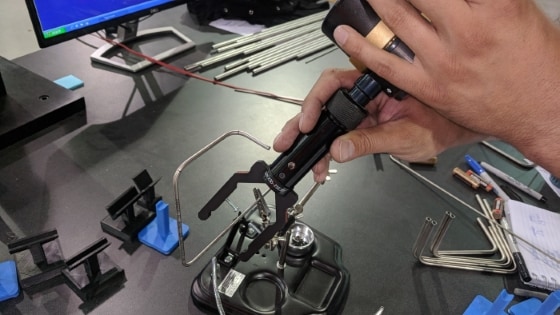

If you’re not new to tube bending, you’ve probably seen, heard of, or even used Swagelok’s line of hand tube benders. These precision tools are built to last and produce brilliant bends with correctly trained hands. But if you’re tasked with scaling your tube bending capability while keeping costs manageable, where do you turn?

We understand your challenge. Repeatable and scalable, our CNC tube bender complements our expanding fabrication and assembly services offering. With the capability to produce both simple and complex, multi-axis bends with incredible accuracy, the Unison Breeze machine bends tubing up to 1 inch (25mm) OD faster and more precise, while simultaneously decreasing waste and rework, than traditional hand tube bending.

Speed and Accuracy

An automated CNC tube bending partner can save time and cost, simplify, and add efficiency to your projects. Parts are created in a fraction of the time that it would take to accomplish manually. Your team can focus elsewhere and you can utilize floor space at your facility for other purposes.

Tube bends can also be integrated into panels and other assemblies at our Swagelok Fabrication and Assembly facility. You receive ready-to-install parts, with no waste and less busywork for your team. The tube bends and tubing assemblies we can manufacture are also backed by the Swagelok Limited Lifetime Warranty.

No Drawing or Measurements? No problem

Often, we’ll have customers come into the shop with a piece of bent tubing that they need to reproduce. Traditionally, we’d inspect the tubing, take measurements, prepare tooling, cut the tubing to length, execute the bend, and review measurements and tolerances against the original.

With our Coordinate Measuring Machine (CMM), we’re able to measure and capture the physical, geometrical characteristics of the existing bent tubing. The CMM then produces coordinates for the precise replica and communicates with the CNC tube bender. The process is seamless, worry-free, and reduces the opportunity for human error. The finished product is the exact identical to the tightest tolerance with no prototyping, waste or re-work.

Our automated CNC tube bending and CMM capability can help streamline your production requirements and bring new efficiencies to your operations by controlling variable labour costs, decreasing the number of connection and potential leak points, and taking advantage of economies of scale. Send us your drawing for quote or visit our facility for a thorough demonstration of this robust capability.